Our companies

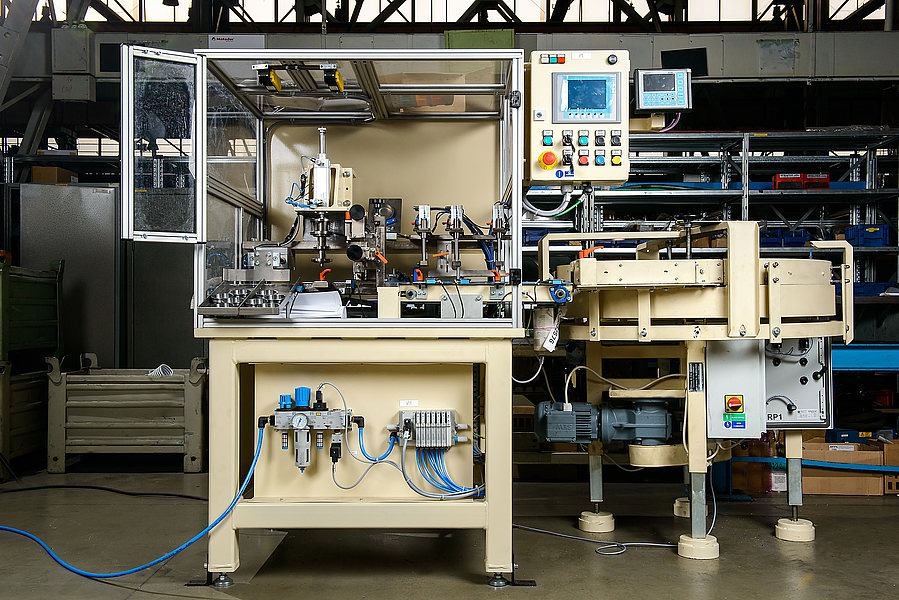

At the engineering office, we utilise CATIA, INVENTOR 2015 and EPLAN to create precise documentation and elaborate analysis before the start of production. This way we make sure that the manufacturing is done in the most efficient way possible, which saves time and money for our customers. We apply our engineering expertise to the preparation of fully and semi–automatic machines and manipulators. Based on the customer’s documentation we prepare the optimal custom turnkey solutions for effective plant automation.

In addition to engineering, we deliver a complete package in terms of assembly, instalment and commissioning of special-purpose machines, manipulators, jigs, fixtures, and conveyor belts as well as a montage of electric, pneumatic and hydraulic components. The large assembly hall possessing an area of 8000 m2 represents sufficient space for a montage of complex assemblies and sub-assemblies of various sizes and shapes.