Our companies

We are a premium TIER 1 supplier of structural components and joined assemblies for the automotive industry with a focus on delivering superior quality and the highest value to our customers. Our services concentrate on the production of cold-formed structural components, which in combination with our fully automatic joining technologies, allow us to deliver complete products within a broad spectrum of sizes and shapes. Due to our high focus on quality and the continuous development of technologies, we have been able to gain a stable position on the market and have become the largest Slovak-originated TIER 1 supplier.

Serial production of cold-pressed structural components is one of our strengths. Using the technical equipment at our disposal, we process traditional steel, ultra-high strength steel as well as lightweight aluminium. Our portfolio consists of hydraulic and mechanical presses that operate in the range of 25 to 2500 tons.

More information

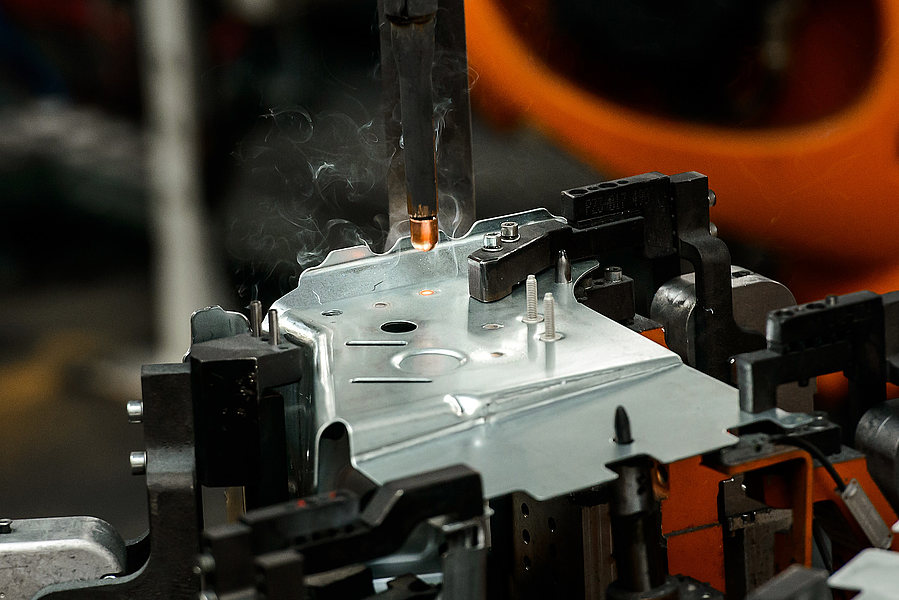

We have established profound expertise in the area of joining cold-formed metal. Successful adoption of a wide range of technologies including self-pierce riveting, welding, screwing, glueing or hemming allows us to produce complex assemblies from different types of material.

More information

Electrophoresis cathode metal coating (KTL) is an extremely efficient and environmentally friendly way of surface treatment. On the in-house KTL line, we perform the coating of structural parts, which have to withstand extreme weather conditions and the toughest effects of the environment. The available facility performs coatings of more than 1 million m2 per year with thicknesses of 15 – 30 µm.

More information

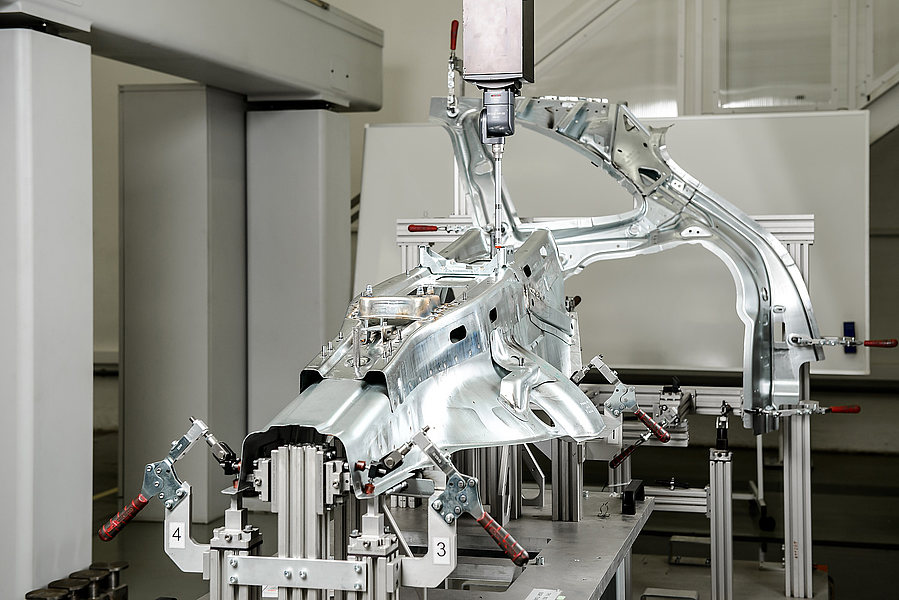

Quality control and material testing have a long tradition in our company. We have the latest 3D measuring equipment in which we carry out non-stop measurement and quality control of products throughout the entire production process.

More information