AUFEER DESIGN introduces cutting-edge P-LPBF technology: Revolutionizing 3D printing for optimal quality, speed, and cost efficiency

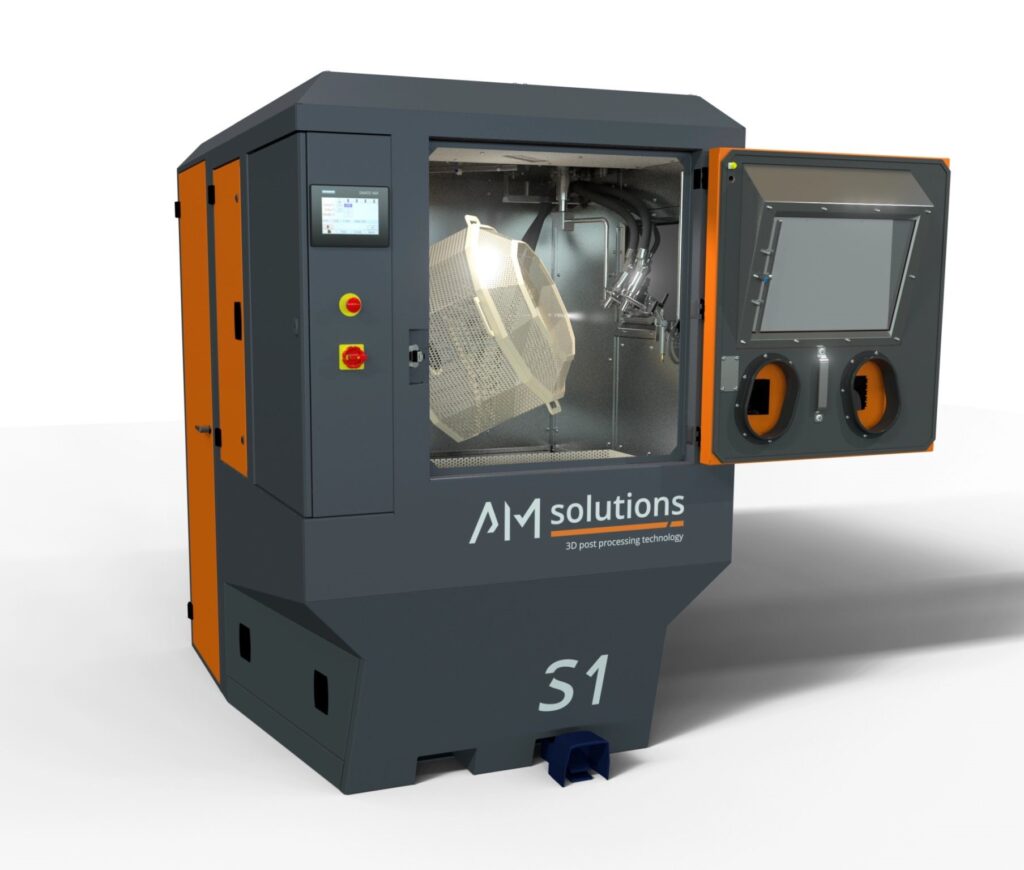

Our company within MATADOR Group, AUFEER DESIGN offers a new competence: P-LPBF technology, which is short for Plastic Laser Powder Bed Fusion, popularly speaking, a top-notch 3D printer.

However, this one is top-notch in its parameters and brings several advantages, such as high production speed, optimal quality and mechanical properties of the built parts, and, of course, lower production costs.

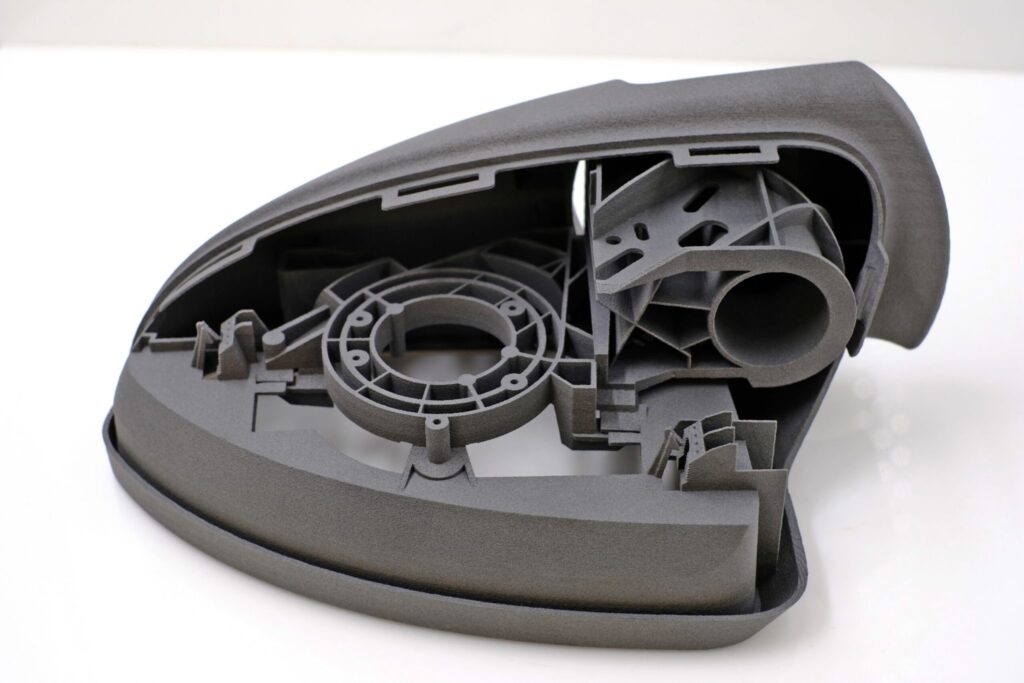

“There is no limit to the shape of the product because it does not need any supporting structure,” explains Tomáš Uhlíř, head of the Clay modelling department, under which the additive manufacturing department belongs. “the method of processing the material takes place in such a way that the final product is created by its gradual controlled addition. Additive manufacturing concerns both polymers and metals. “We have taken a huge step forward with regard to the complexity of our offer,” adds Tomáš Uhlíř. “Creativity in the form of additive thinking allows us to look for innovations and business models together with our customers that would not be possible with conventional methods.”

The operation hall in Josefův Důl near Mladá Boleslav officially started its activity in March this year, but the first orders were already reported a few weeks before. According to Tomáš Klepl, the head of the department, the competencies of this division can be divided into two categories. “We offer small-series additive manufacturing, where the main advantage is the “just in time” approach and the possibility of immediate modification of the design and modification of parts exactly according to the customer’s requirements.

Additive manufacturing offers a great opportunity to overcome supply chain problems: overproduction with required volumes, high storage costs and long delivery times. 3D printing now offers efficient on-demand production of spare parts and digital inventory to avoid heavy warehousing and logistics costs,” sums up Tomáš Klepl, Head of Additive Manufacturing.